PURPOSE

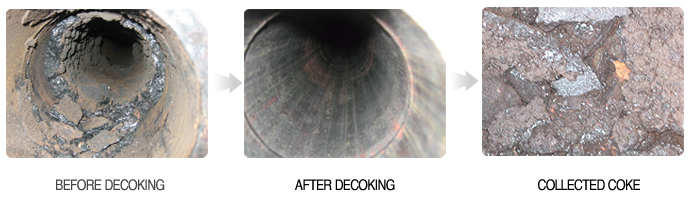

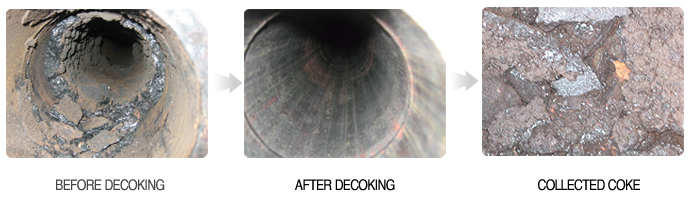

To get stable flow rate,To expend life span of tube by preventing bulging, To prevent heat loss and raising pressure by removing coking deposit, carbon of inside wall of tube

General Work Procedure

- 1) Removing valve, flange, spool and attached equipment : For getting work space, For smooth pig run.

- 2) Install Launcher, Receiver and pressure utility : Preparation work for decoking

- 3) Water flushing(P check) : To check passing possibility and condition of inside of pipeline

- 4) Foam pigging(KIS-NCW) : To remove soft coke and check scale

- 5) Hard foam pigging (KIS-NCB) : Actual work for removing coke by using high density foam pig

- 6) Metal pin pigging (KIS-SMPS3) : To remove high density coke. Metal pin pigs come and go many times inside of pipeline

- 7) Foam pigging(KIS-NCW) : To remove remained scale after Metal pin pigging

- 8) Water flushing(P check) : To remove tiny scale

- 9) Water drain(KIS-SWA1/KIS-SWA3) : To remove water and scale mixed in air

- 10) Inspection

- 11) Uninstall equipment and restore the pipeline