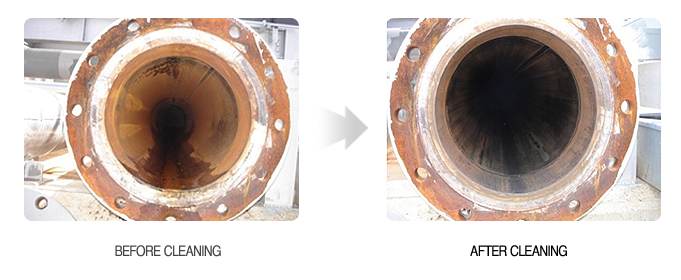

PURPOSE

To service liquid as the best quality by removing remained debris, rust, send, must and welding spatter inside of pipeline which is arising during construction or long term outdoor storage.

General Work Procedure

- 1) Removing valve, flange, spool and attached equipment : For getting work space, For smooth pig run.

- 2) Install Launcher, Receiver and pressure utility :Preparation work for Pig Cleaning

- 3) Air Blowing : To check whether air getting through inside of pipeline and condition of pig operation using air compressure.

- 4) Foam pigging(KIS-NCW) : To check condition of water and debris.

- 5) Brush Pigging (KIS-SPB1) : To remove rust or debris. Adjust pigging times as the quantity of debris. Metal brush is attached on the pig surface.

- 6) Sponge Pigging (KIS-SWA1) :To remove rust and debris after brush pigging.

- 7) AIR BLOWING : To remove dust, or tiny debris.

- 8) INSPECTION

- 9) Uninstall equipment and restore the pipeline