INSPECTION

스킵 네비게이션

메인메뉴

KOINS PIG

INSPECTION

하위메뉴

본문 내용

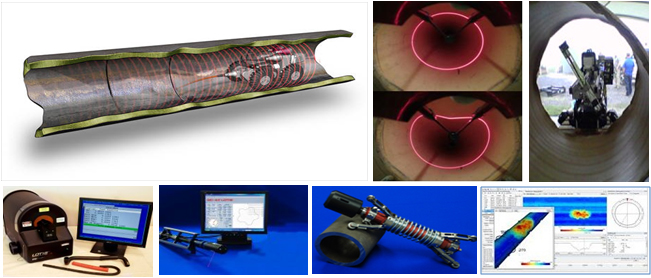

LASER PROFILER INSPECTION 서비스

- 가.서비스 개요

레이저 프로파일러는 파이프 내부에 레이저를 조사, 신규 및 기존 파이프 라인의 난형도, 용량, 변형, 침식, 측면 돌출부,

표면 손상 등의 정확한 데이터를 제공합니다.

본 서비스는 라이닝 전과 후에 허용오차 1mm 이내의 정확한 파이프 상태의 분석을 통하여

노후관 갱생에 있어서 더 우수한 설계 및 시공을 보장합니다.

- 나.측정 데이터

난형도(Ovality)

부식정도(Corrosion)

모재 로스(Material Loss)

관경(Diameter)

퇴적물 깊이(Sediment Depth)

잔존수명 예측(Life Expectancy)

결함, 구멍 또는 기타 이상 유무 체크(Defect Check)

- 다.활용방안

Measuring the thickness of relining.

Identifying and measuring pipe wall erosion to predict structural failure.

Characterizing the deposition of debris, grease and corrosion.

Measuring tap protrusion.

Diagnosing pipe eccentricity, partial collapses and other dimensional anomalies.

- 라.참고사진

LOTIS® based products (from left to right: LOTIS® QC-20, LOTIS® QC40, LOTIS® 600, software)

개인정보취급방침

저작권표시, 주소 및 연락처

- COPYRIGHT (C) 2011 Koins Co., Ltd. ALL RIGHTS RESERVED.

- 본사및 공장 : Tel. 061-684-6862 Fax. 061-684-6865 (59602) 전라남도 여수시 율촌면 율촌산단3로 297 / 사업자: 417-81-31578 / Mail : Koins@Koins21.co.kr

- 울산지점 : Tel. 052-239-5335 (010-9763-8777) Fax. 052-237-5665 (45000) 울산광역시 울주군 온산읍 덕신로 402-2 203호

- 대산지점 : (31900) 충남 서산시 대산읍 평신1로 531-45 103호

- 인도법인 : Tel: +91-2640-661035 Fax: +91-2640-661533 Plot No.C-1.Vile-BhagadMIDC Industrial Area, Tal-Mangaon, Dist-Raigad, Maharashtra?402308, INDIA