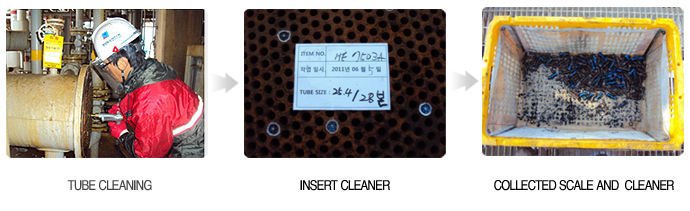

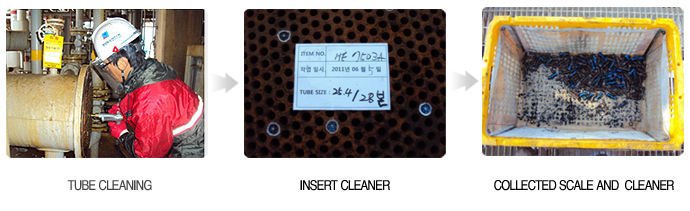

PURPOSE

To keep flow rate and pressure stable by removing debris inside of tube and get best efficient heat exchanging effect

For preparation before mechanical defect inspection.

STRONG POINT OF HEAT EXCHANGER TUBE CLEANER

- 1) Nearly 100% Tube Cleaning : Not Possible Of Missing Tube

- 2) Constant Velocity And Pressure Cleaning : Ensure Cleaning Quality

- 3) Under Deposit Scale Cleaning : Possible To Collect Scale As It Discharged With Some Water

- 4) Shorten The Working Time Compared With Water Jet Cleaning : Based On One Time Shooting, 400~600 Holes

- 5) Also Used On The Regular Maintenance Of Surface Condenser : Supplied The Weakness Of Automatic Tube Cleaning System

- 6) When Thin And Hard Scale Is Formed On The Internal Wall : Destroy It Using Special Thin Hard Scale Remover

- 5) Hard Foam Pigging (Kis-ncb) : Actual Work For Removing Coke By Using High Density Foam Pig

- 6) Metal Pin Pigging (Kis-smps3) : To Remove High Density Coke. Metal Pin Pigs Come And Go Many Times Inside Of Pipeline

- 7) Foam Pigging(Kis-ncw) : To Remove Remained Scale After Metal Pin Pigging

- 8) Water Flushing(△p Check) : To Remove Tiny Scale

- 9) Water Drain(Kis-swa1/Kis-swa3) : To Remove Water And Scale Mixed In Air

- 10) Inspection

- 11) Uninstall Equipment And Restore The Pipeline

Home

Home