OUTLINE

content

- To Lead Stable Operation Of Pipeline By Inspecting Various Defect Or Corrosion.

- ① General Inspection For Integrity Of Pipeline

- ② Total Assessment For Location And Condition Of Corrosion

- ③ Assessment For Remain Life Span Of Pipeline

- ④ To Make As Built Drawings By Geometry, Mapping Of Pipeline Route And Navigation System

- ⑤ Procure General Data For The Pipeline With Regular Inspection And Get Initial Data For New Pipeline

- ⑥ And So On

- Site Survey → General Plan And Preparation → Reforming Existing And Temporary Pipeline → Manufacture Launcher And Receiver → Cleaning Pig Run → Gauging Pig Run → Dummy Pig Run (If Required) → Geometry Survey Pig Run(If Required) → Corrosion Survey Pig Run → Submission Of Field Report → Demobilization From Work Site → Submission Of Final Refort Within 46days After Complietion

PURPOSE

APPLICATION

GENERAL PROCEDURE OF INTELLIGENT PIGGING

TOOLS

|

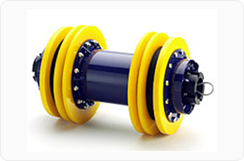

CLEANING TOOL The economic bi-directional disc model for general cleaning and all (pre-)commissioning applications such as gauging, water filling, pressure testing, dewatering, and drying.Long operating life due to highly wear-resistant polyurethane materials Tool Accessories Circular brush / Set of magnets / Gauge plate Tool location transmitter / Electronic Pig Detector |

|

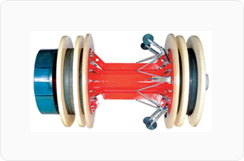

ELECTRONIC GEOMETRY TOOL Electronic Geometry Tool Obstructions are then identified, sized, and located. In addition to the detailed geometric data features (i.e. bends, ovalities and dents), ROSEN’s RoGeo also provides auxiliary data relating to operating conditions such as speed and temperature. THE KEY BENEFITS - Accurate, robust, and reliable - 100% circumferential coverage with overlapping sensor measurement - Detects dents, installations (valves, tees, flanges, welds, etc.), ID-changes, ovalities, and bends - Evaluation of recorded data within a few hours to include:Speed profile and Temperature profile |

|

CORROSION DETECTION TOOL Magnetic Flux Leakage inspection tools are a reliable and effective means of managing your pipeline’s integrity for corrosion, erosion, gouging and other metal loss features. Unique magnet and sensor designs ensure high sensitivity and accuracy. THE KEY BENEFITS - Accurate, robust and reliable - Fast, accurate data analysis and reporting - Tool designs ensure ease of operation and flexibility. |

|

ULTRASONIC CORROSION DETECTION TOOL it provides enhanced measurement capabilities for large areas of uniformly-corroded metal loss and laminations. THE KEY BENEFITS - Accurate, robust and reliable - Ensures fast, accurate data analysis and reporting - Full circumferential coverage with high detection accuracy - Can be used in combination with other inspection technologies to increase inspection efficiency: Magnetic Flux Leakage, extended Geometry |

|

COMBINED MFL/ULTRASONIC DETECTION TOOL Combined MFL/Ultrasonic Corrosion Detection Tool employs twin inspection technologies to achieve enhanced performance in defect detection and sizing. Ultrasonic Technology (UT) can detect and accurately size defects where Magnetic Flux Leakage (MFL) technology has limitations, for example, large areas of uniformly-corroded metal loss and laminations. Conversely, MFL technology can detect and size defects where ultrasonic technology has limitations, for example small corrosion pits and internal defects covered by wax or other deposits. With a combined MFL/UT tool, the strengths of both inspection methods provide the most comprehensive detection and sizing results in the market from a single run. THE KEY BENEFITS - MFL and UT results in one inspection run - Accurate, robust and reliable - Fast, accurate data analysis and reporting - Tool designs ensure ease of operation and flexibility - Ancillary system ensure easy and accurate feature location |

Home

Home