목 적

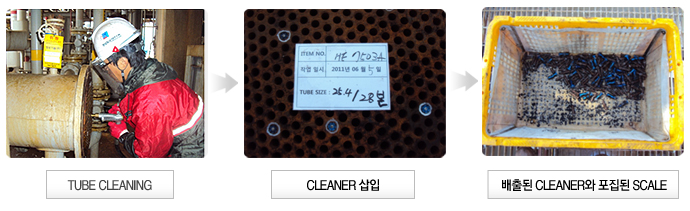

PIG CLEANER를 이용하여 TUBE 내벽에 있는 이물질들을 완벽히 제거함으로써 유량 및 압력을 신규 제작 당시에 근접하게 하여 최상의 열 교환 효과를 얻게 하고 TUBE 내부의 기계적 결함 검사 시 문제가 없도록 하는데 그 목적이 있다.

HEAT EXCHAGER TUBE CLEANER의 장점

- 1) 100%의 완벽한 TUBE CLEANING : CLEANING을 하지 않고 지나치는 MISSING TUBE 발생 가능성 불허

- 2) 일정 속도와 압력으로 CLEANING : CLEANING QUALITY 보장

- 3) TUBE내 UNDER DEPOSIT SCALE 부위 CLEANING 가능 : SCALE이 소량의 물과 함께 배출됨으로서 SCALE 포집 가능

- 4) WATER JET CLEANING 방식에 비해 작업 시간 단축 : 1회 SHOOTING 기준으로 시간당 400~600 HOLES 가능

- 5) 해수를 이용하는 발전소 등의 SURFACE CONDENSER 등에도 정기 보수 시 적용 : ON-PROCESS상에 장착된 BALL 형태의 ‘자동 튜브 CLEANING SYSTEM’ 의 한계 및 단점 보완

- 6) 얇고 단단한 SCALE 이 TUBE 내부에 전반적으로 형성되어 있는 경우 : THIN HARD SCALE REMOVER 라는 특수 형태의 CLEANER를 사용하여 SCALE 1차 파쇄 작업 가능

Home

Home